About us

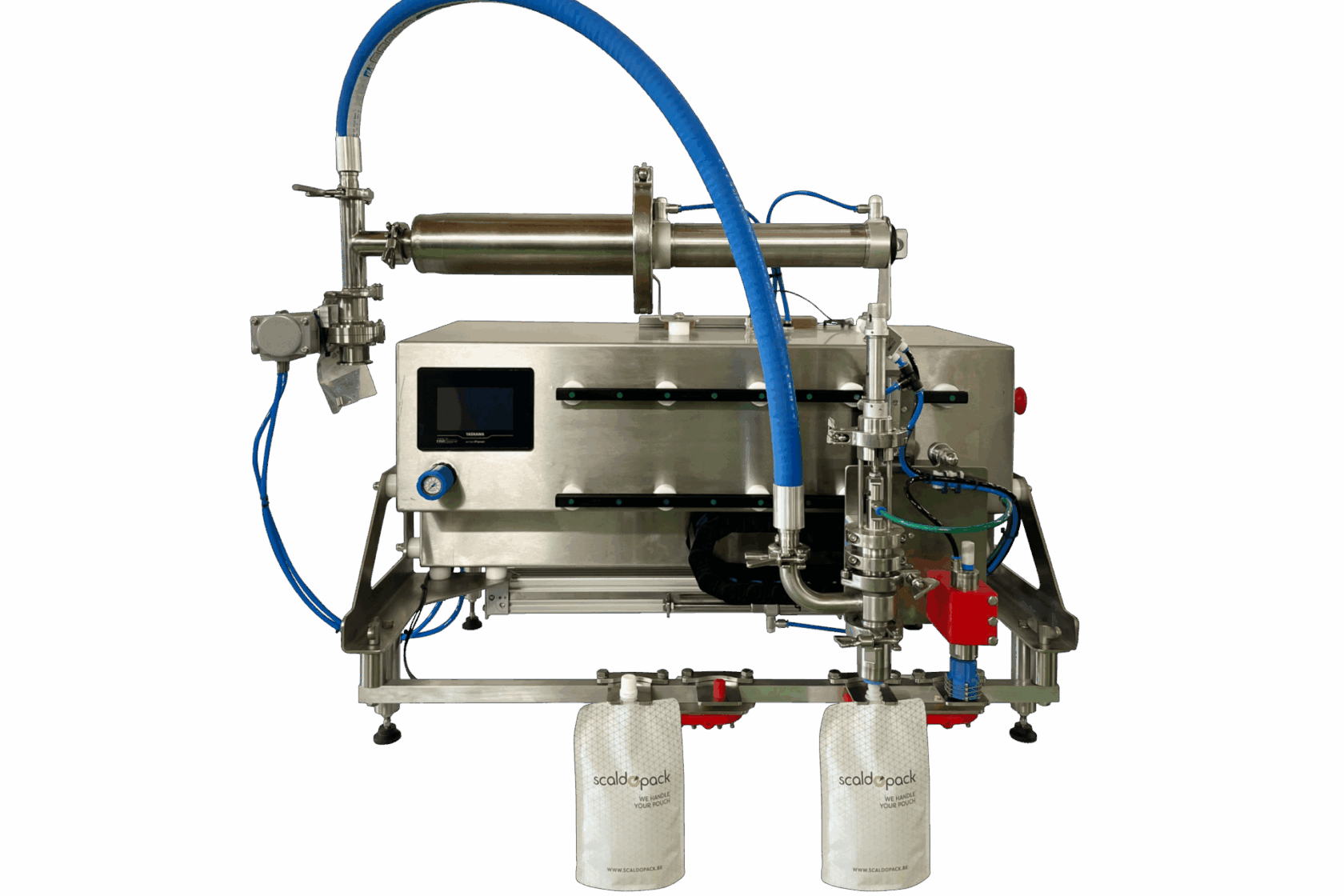

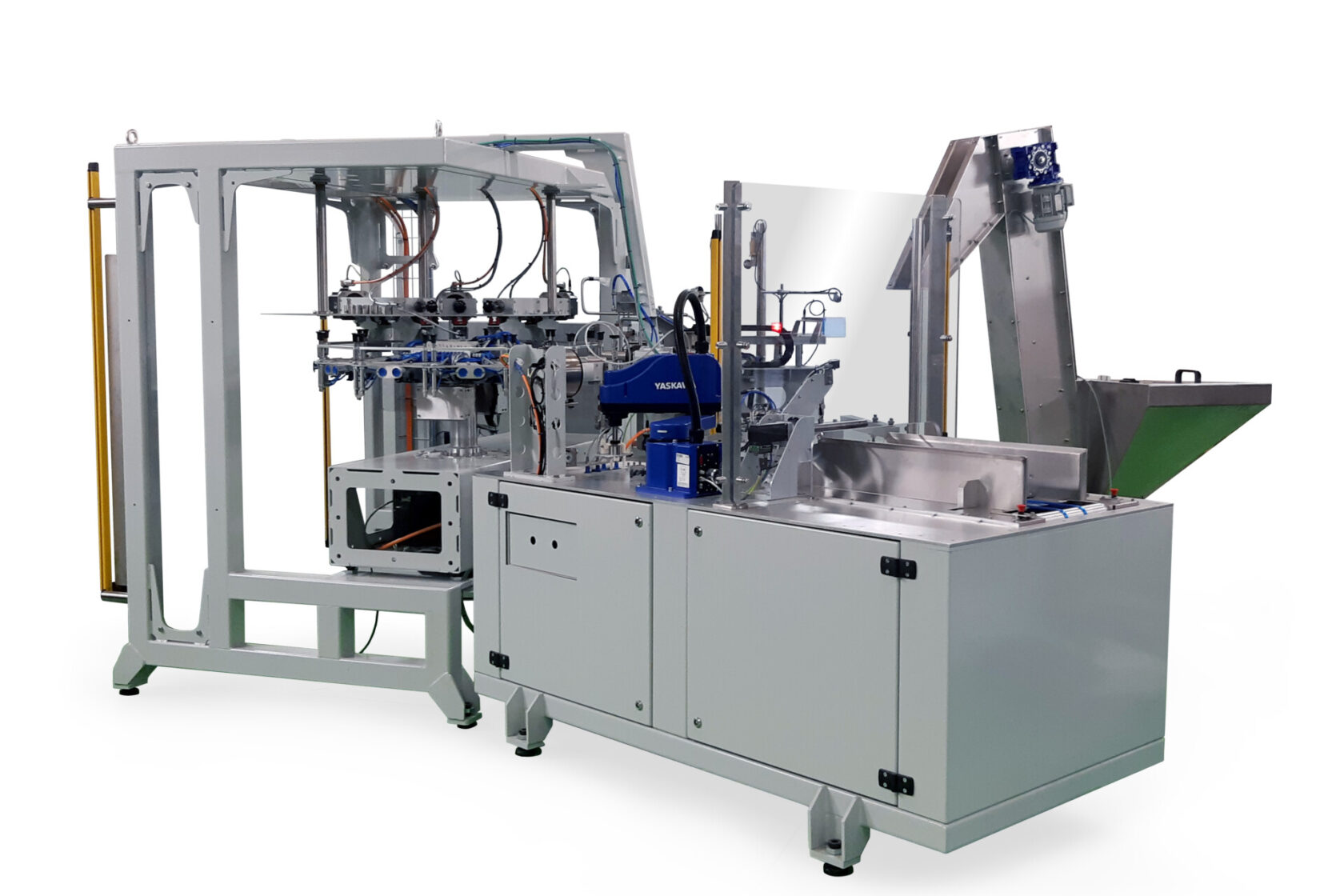

Scaldopack develops, produces and services advanced pouch spouting and pouch filling and capping machines. Our mission & commitment towards our customers is to deliver production machinery of unrivaled quality with a minimum of defaults.

High quality machine building, advanced mechatronics & good and stable production speed result in a high-end piece of production machinery that will keep you smiling all the way.

Why do our customers choose Scaldopack?

Economical

Scaldopack machines have a smashing return on investment and net present value. Depending on the production customers have, some machines have a payback period of less than a year before they start to deliver pure return on investment. When considering an investment you want your TCO as low as possible, right?

With less downtime, advanced detection features by using servo motors, machine learning, etc… you are sure to beat your competition in a jiffy.

As the change over time between 2 production cycles is reduced to hours or even less than 30 minutes, the human labour costs will decrease significally.

Experienced

We offer our customers years of experience acquired through extensive research to compose machinery perfectly compliant to rules, laws and local regulations. These machines are tailored to your needs. An in-house engineering department diligently looks at your demands and will propose a packaging machine fully up to its future task.

Flexible

Consumer markets are changing faster than ever. This demands a flexible approach throughout your supply chain. What a customer perceives as excellent today, may be obsolete by tomorrow in the current business context. We understand this predicament and need for adaptability. You need a lean dependable partner who will answer this challenge with the right solution for you. Customers love our lean and adaptable approach to their packaging problem and they know we aim for optimal customer satisfaction.

Internationally active

Located in Belgium, Scaldopack also has local agents and dealers all over the world and is still establishing new partnerships every day. We’re coming to you!

Environmental

As worldwide demands from government institutions to implement ecology friendly technology is seriously gaining momentum, many producers in industry are under constant scrutiny to improve their own production methods. We offer next generation packaging machines to satisfy the public opinion.

- Scaldopack is one of the first in the industry to be able to seal monolayer films.

- Up to 75 % less energy consumption during production in comparison with conventional packaging machinery

- Up to 70 % less use of hard plastics in comparison with traditional packaging methods

- A design for spout filling technology to reduce waste during the filling process of the pouch.

Quick change overs

Electronic motors from Scaldopack with low energy consumption, permit a nearly automatic repositioning of machine workstations.We have drastically reduced the time needed for a change over from multiple days/hours to anything between 10 to 30 minutes.

EHEDG

All Scaldopack machinery is built according to the EHEDG standards to meet hygienic requirements most of our customers have to comply to.

(EHEDG = European Hygienic Engineering & Design Group)

Compliant

The machine is compliant to the Machinery directive 2006/42/EG.

History

The company founded by Harald Saelens & Henno Hensen managed to combine the expertise knowhow of Henno Hensen in pouch handling with an extensive knowledge of chemicals to develop self-heating and self-cooling pouches.

They noticed the conventional machinery available on the markt was not able to deliver a consistent product when it came to the point of continuosly producing self-heating packages of outstanding quality.

At Scaldopack we combine key characteristics of traditional knowhow with advanced modern mechatronic machinerydesign to make dedicated production machinery for great pouches. By combining tradition and future together we deliver state of the art machinery for spouting and filling.

During our evolution into machinery development and fabrication we eventually abandoned self-heating and self-cooling products as we saw the demand in the market for pouch sealing and filling machines.

Scaldopack is focused on building advanced packaging machinery meeting your requirements, your needs and wants.

Your satisfaction as another Scaldopack customer means the world to us.