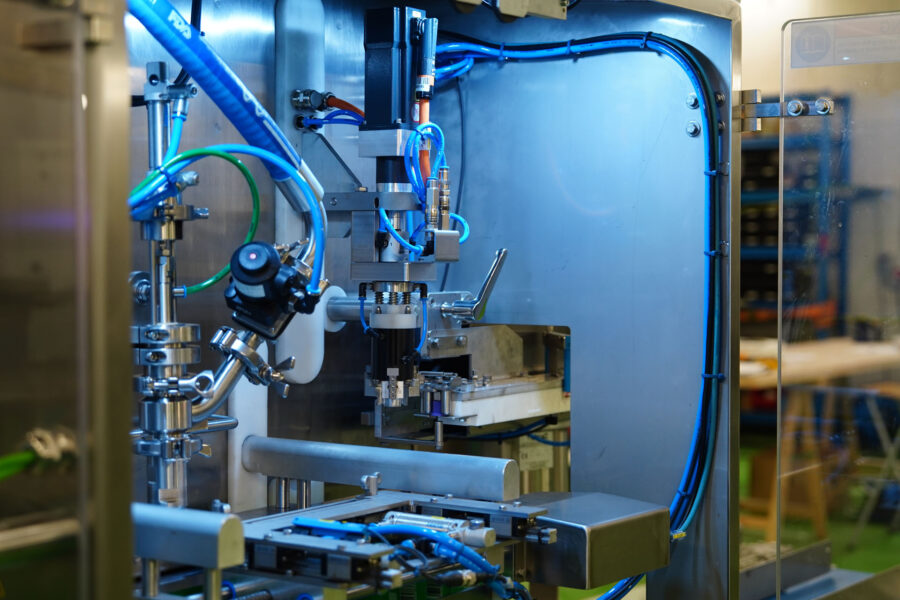

Monofiller Multihead 2: Automatic dual-head filling and capping machine

The Monofiller Multihead 2 is a high-performance spout pouch filling and capping machine built for producers and co-packers who demand speed, hygiene, and precision. This automatic filling machine features a dual-head (multihead) configuration, capable of filling and capping up to 80 pre-spouted pouches per minute — even for viscous or particulate-rich products.

⚙️ Want to scale up your pouch filling line? Go have a look at our solutions.

Multihead efficiency for demanding production lines

The Monofiller Multihead 2 is our automatic pouch filling through the spout and capping machine. Thanks to its dual filling and capping heads, the Multihead 2 doubles the capacity of the standard Monofiller. It’s built for producers filling large volumes of liquid or semi-liquid products, from food and beverages to cosmetics and household goods. It can fill top and/or corner spouted pouches.

This automatic multihead spoutfiller is especially suited for:

Filling viscous products (with or without particulates)

Capping pre-spouted pouches with high precision

Running small or medium pouch formats at high speed

Automated filling of pouched for foods and non-foods

Whether you’re packaging fruit purées, sauces, gels, or personal care products, the Multihead 2 ensures clean, consistent output — pouch after pouch. More specifically, it can be used for:

- Food such as baby food, dips, hummus, sauces, peanut butter, honey, yoghurt, juices, alcoholic beverages.

- Non-food such as gels, shampoo, lotions, soaps, conditioner, cleaners, softeners, automotive oils and adhesives.

This machine can be custom designed and built with a range of different options according to your filling conditions, product(s) to fill and size of your pouch or your spout.

The Monofiller Multihead 2 is also available with outfeed conveyor and buffer station.

Clean spout filling machine with EHEDG design

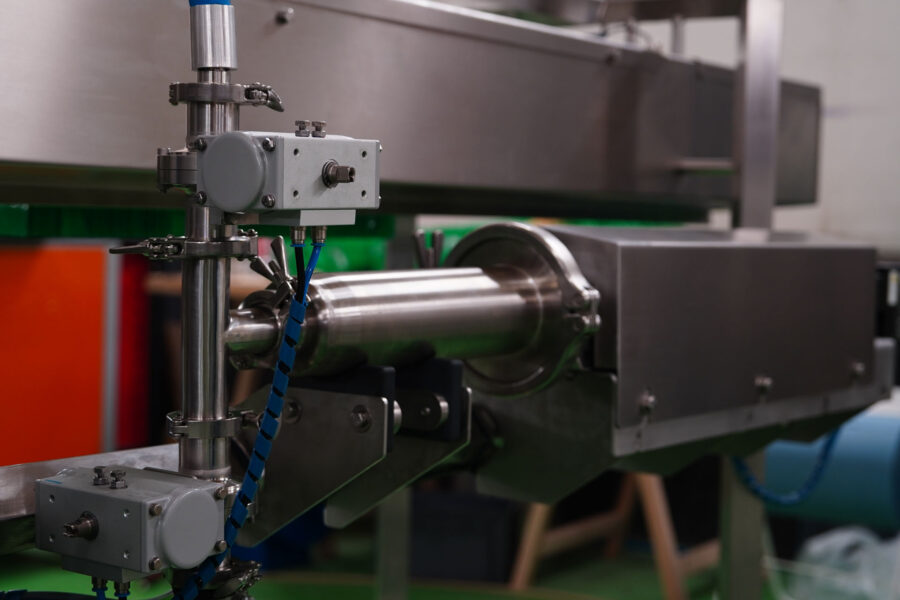

Just like the standard Monofiller, the Multihead 2 fills directly through the spout, keeping the seal zone clean. It complies with EHEDG (European Hygienic Engineering and Design Group) guidelines and offers:

Clean-In-Place (CIP) readiness

Servo-controlled filling pumps

Splash-free, accurate dosing

Full separation between product path and mechanics

The result: a clean, efficient and future-proof filling solution.

Key features of the Monofiller Multihead 2

Dual-head filling and capping

Compatible with most pre-spouted pouches

Servo-driven dosing system for maximum precision

Compact frame, front-accessible for maintenance

Suitable for food and non-food applications

Upgradable to integrate with existing pouch filling lines

The Multihead 2 can be installed as a standalone unit or linked into a larger automatic pouch filling and packing system.

For spout and standup pouch production at scale

If your production requires more than one head, the Monofiller Multihead 2 offers a smart balance between speed, hygiene and footprint. It’s ideal for:

Mid-sized manufacturers

Co-packers scaling their spouted and standup pouch packaging lines

Businesses needing fast format changeovers with full automation

Ready to expand with the Monofiller Multihead 2 automatic filling machine?

The Monofiller Multihead 2 is a future-ready spoutfiller that brings performance and hygiene together. Whether you’re filling pouches for food, cosmetics, or industrial products, this multihead system is built to meet your demands — efficiently and cleanly.